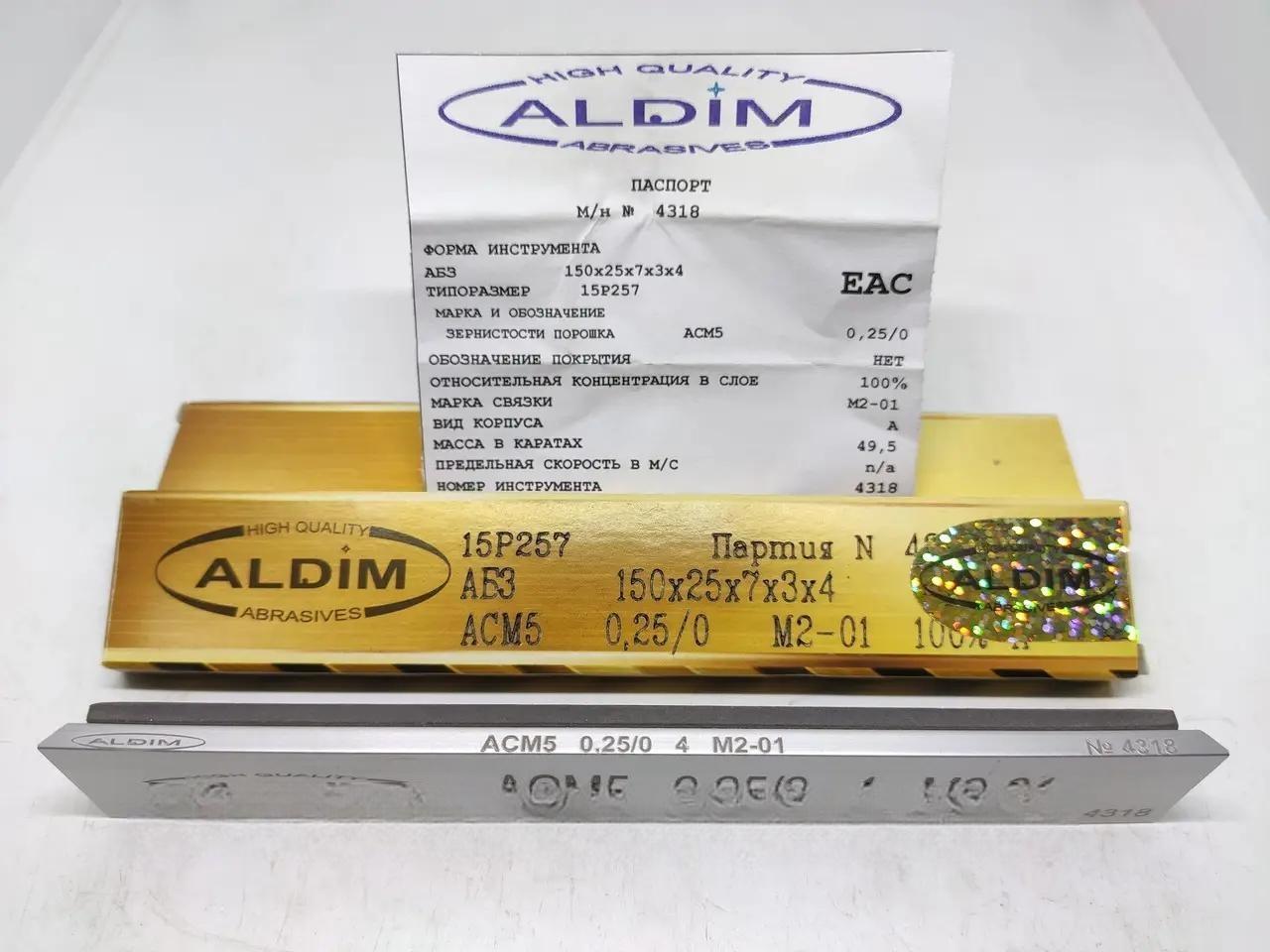

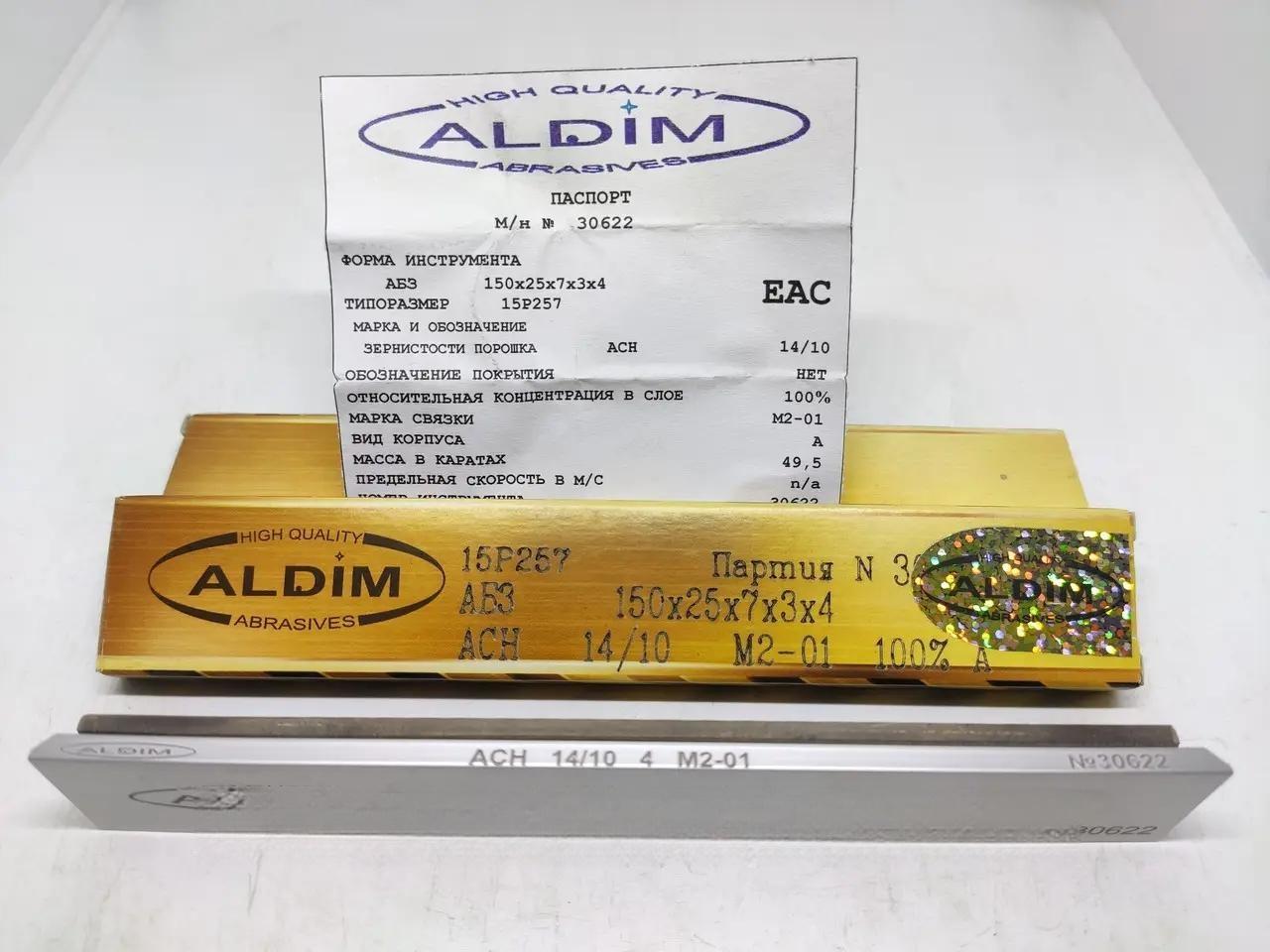

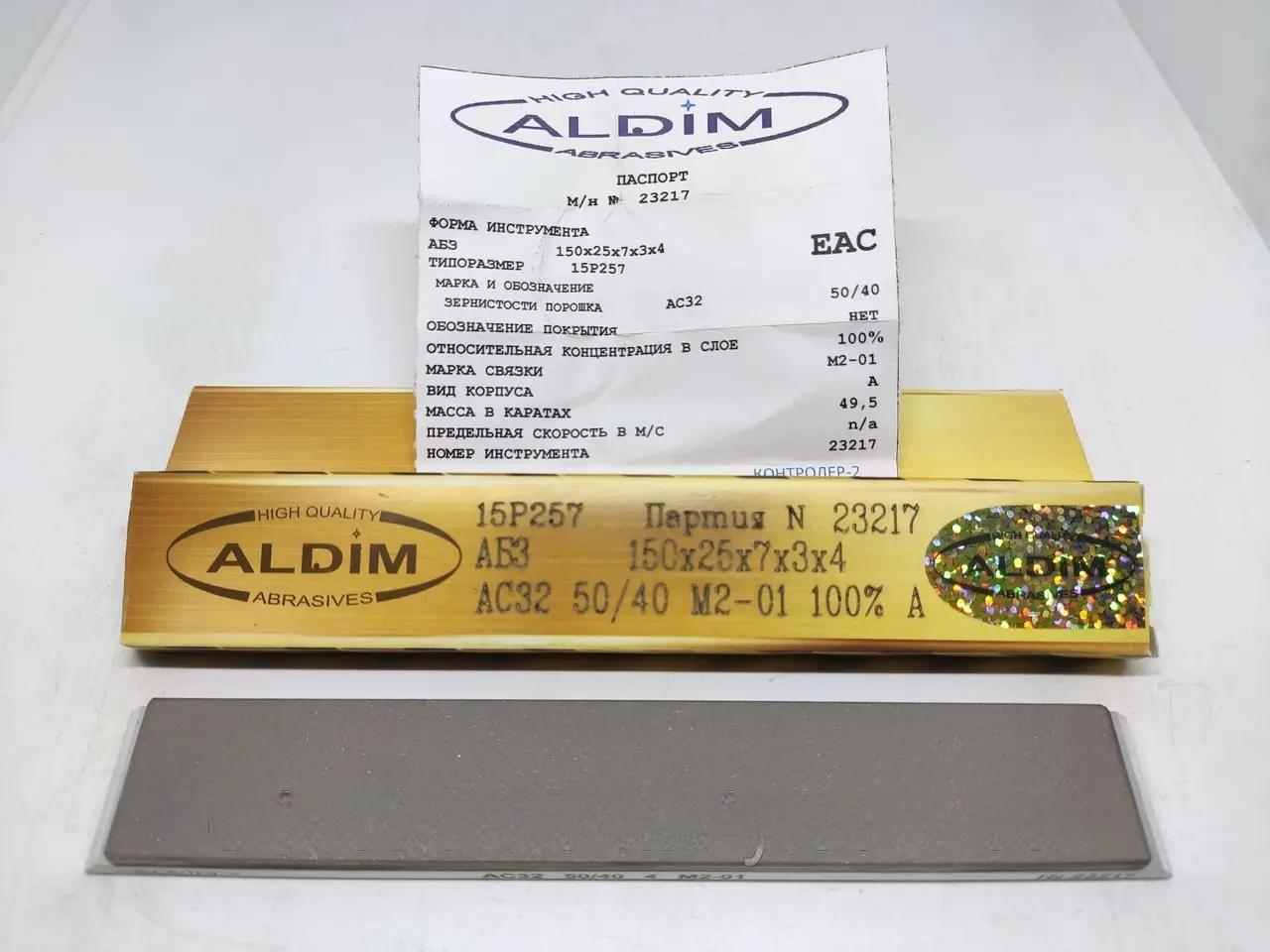

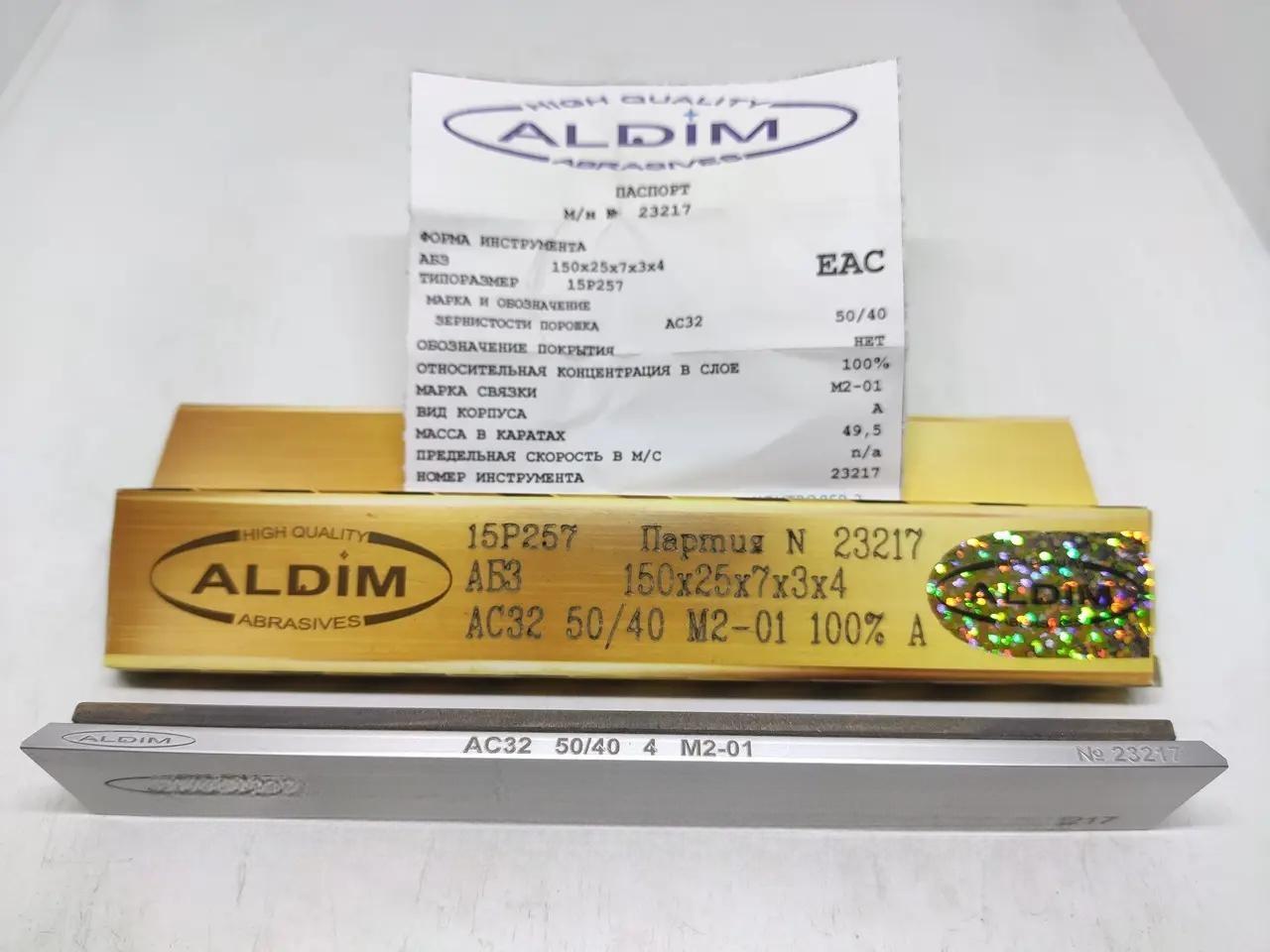

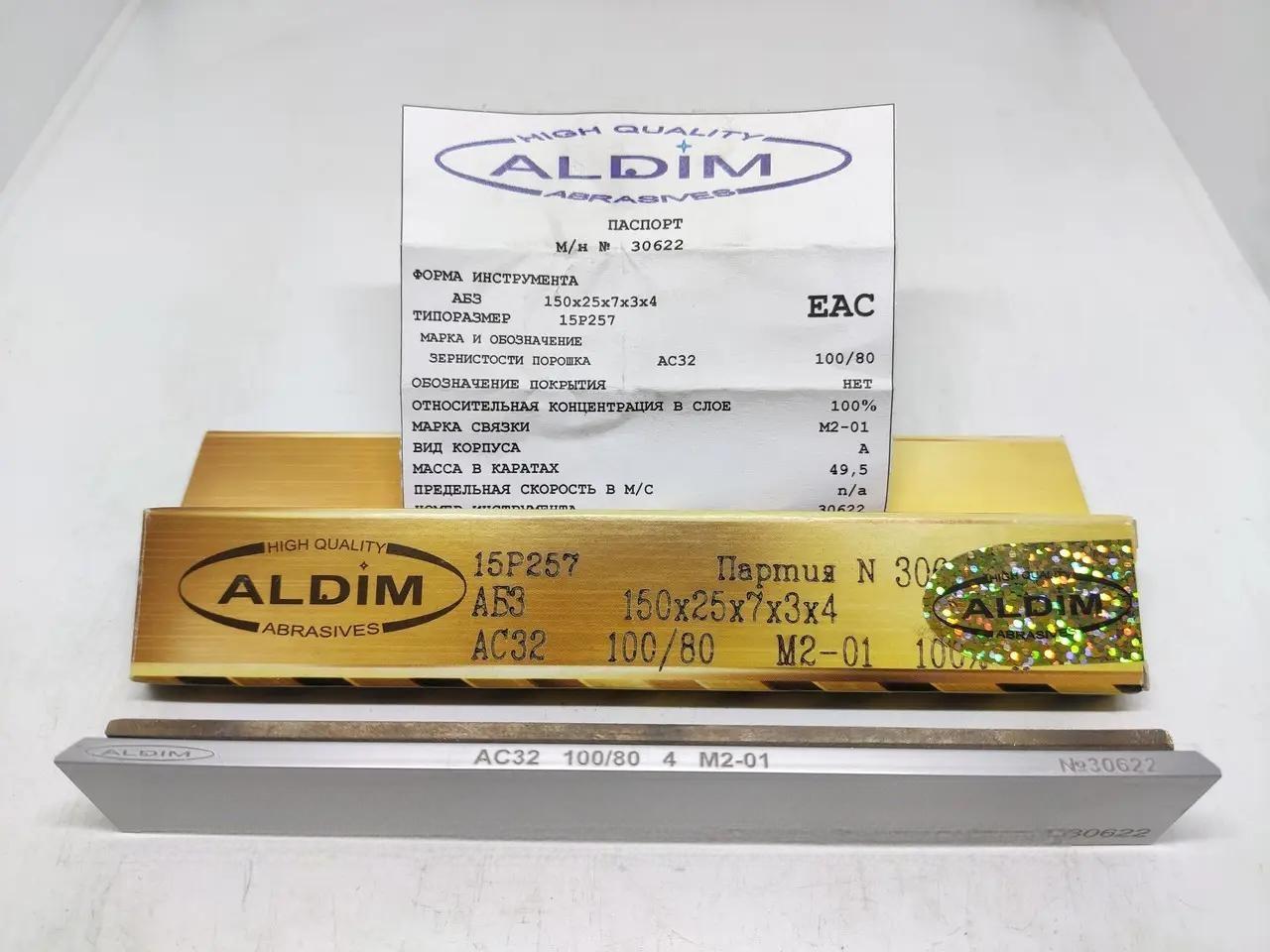

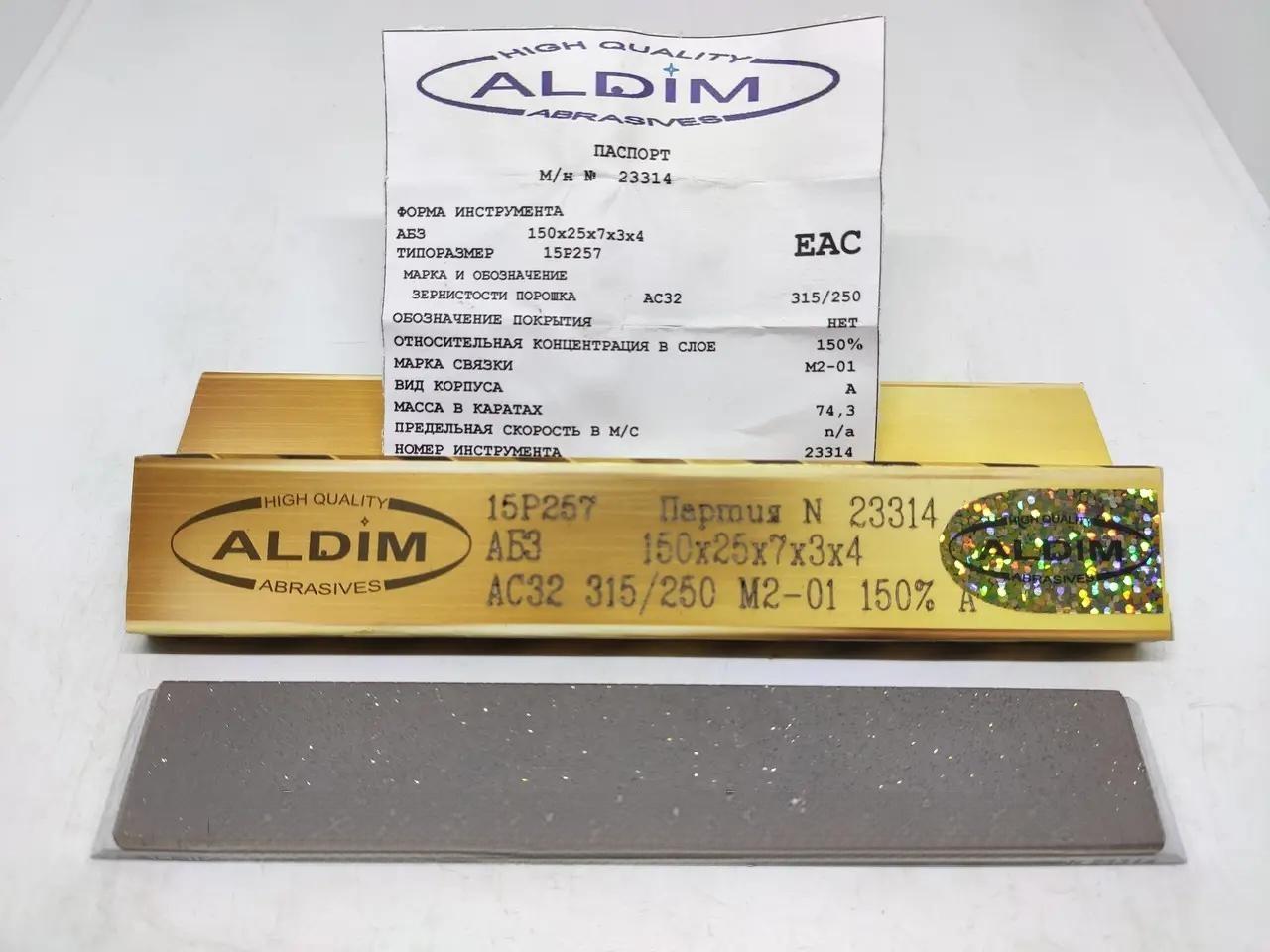

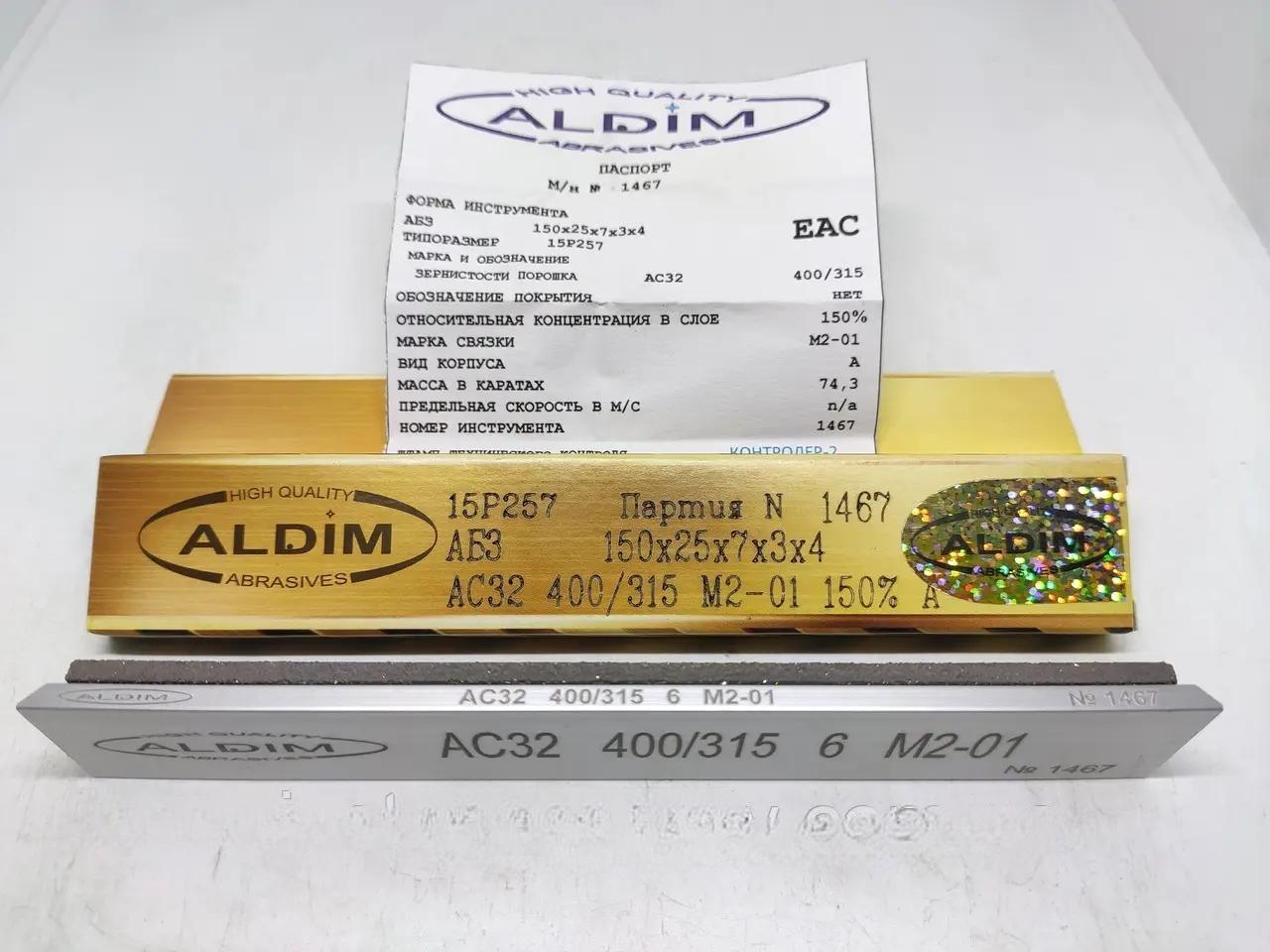

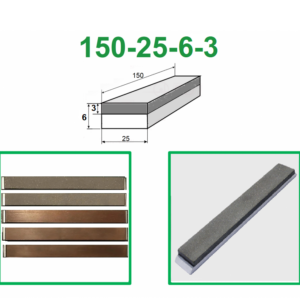

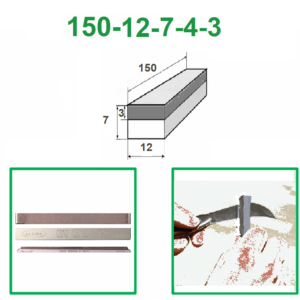

150 х 25 х 7 x 3 x 4

CBN is the second-hardest material after diamond, and has the best price-performance ratio for processing steels, comparing to other materials, including diamond, silicon carbide or aluminum oxide. Due to it’s high resistance specs, CBN can be used dry without lubricant. This makes CBN the cleanest of the available sharpening stones. For high alloy steels (eg. X50CrMoV15), with hardness 60HRC and more we recommend using diamond sharpening stones.

Trademark: Aldim. Made in Ukraine by Poltava plant of diamond tools

Length: 150 mm = 6 inch

Width: 25 mm x = 1 inch

Total thickness: 7 mm = 0.28 inch

CBN thickness: 3 mm = 0.12 inch

Blank thickness: 4 mm = 0.16 inch

Compatible with Apex Edge Pro, RUIXIN, TSPROF, Hapstone, etc. Due to the softness of the hybrid bond, these sharpening stones are best suited for knife finishing. At the same time these stones have working life, similar to that of metal bond stones.

For sharpening of carbon steels we recommend using cubic boron nitride sharpening stones

Recommendations on selection of sharpening stones

How to maintain sharpening stones

Metal bond, ensures high endurance and low wearing rate, may require lubricant

Grain size: Please select from the list, or read Technical information.

In grain selection window you see grain sizes according to standards:

MESH(GRIT)=MICRON

Do not waste your money on cheaper stones with lower/unknown concentration.

Flat solid block on aluminum blank, abrasive grains are evenly distributed across the volume of the stone.

Preparation of sharpening stones

Unlike other sharpening stones, most of these hybrid bond stones do not need preparation, except stones with grits finer 1 microns (<Grit 15000). Ultrafine grains (1/0, 0.5/0) form agglomerates in a bond, so you may need to dress them with abrasive powders/pastes, or they will be self-polished after sharpening of 30-50 knives.

Selection of SiC powders for dressing of sharpening stones

| Stone | Starting grit | Finishing grit |

| 500/400 μ = 35/40= D501 | F16 (1230 μ) | F24 (745 μ) |

| 400/315 μ = 40/45= D426 | F16 (1230 μ) | F46 (370 μ) |

| 315/250 μ = 50/60= D301 | F24 (745 μ) | F46 (370 μ) |

| 250/200 μ = 60/70= D251 | F24 (745 μ) | F60 (260 μ) |

| 200/160 μ = 70/80= D213 | F36 (525 μ) | F60 (260 μ) |

| 160/125 μ = 100/120= D151 | F46 (370 μ) | F80 (180 μ) |

| 125/100 μ = 120/140= D126 | F60 (260 μ) | F100 (129 μ) |

| 100/80 μ = 140/170= D107 | F60 (260 μ) | F120 (109 μ) |

| 80/63 μ = 170/200= D91 | F80 (180 μ) | F150 (82 μ) |

| 63/50 μ = 230/270= D64 | F100 (129 μ) | F180 (69 μ) |

| 50/40 μ = 270/325= D54 | F120 (109 μ) | F220 (58 μ) |

| 40/28 μ = 550= M40 | F150 (82 μ) | F240 (46 μ) |

| 28/20 μ = 650= M25 | F180 (69 μ) | F320 (30 μ) |

| 20/14 μ = 1100= M20 | F240 (46 μ) | F400 (18 μ) |

| 14/10 μ = 1500= M16 | F320 (30 μ) | F400 (18 μ) |

| 10/7 μ = 1700= M10 | F400 (18 μ) | F600 (10 μ) |

| 7/5 μ = 3000= M6.3 | F600 (10 μ) | F800 (6,7 μ) |

| 5/3 μ = 4000= M4 | F600 (10 μ) | F800 (6,7 μ) |

| 3/2 μ = 6000= M1.5 | F800 (6,7 μ) | F1200 (3 μ) |

| 2/1 μ = 10000 | F800 (6,7 μ) | F1200 (3 μ) |

| 1/0 μ | F800 (6,7 μ) | F1200 (3 μ) |

| 0.5/0 μ | F800 (6,7 μ) | F1200 (3 μ) |

Use and cleaning of diamond sharpening stones

Use any comfortable oil (baby, olive..) to prevent glazing. If glazed – clean with alcohol and toothbrush.

Maintenance (in 1-2 years), flattening/revitalization – with silicon (silica) carbide powders on glass plate, grain size selection – according to the table above.

Grain size/operation reference chart

30000 grit = 0.5/0 μ – fine polishing

15000 grit = 1/0 μ – fine polishing

10000 grit = 2/1 μ – fine polishing

5000 grit = 3/2 μ – fine polishing

4000 grit = 5/3 μ – polishing

3000 grit = 7/5 μ – polishing

1700 grit = 10/7 μ – polishing

1500 grit = 14/10 μ – polishing

1100 grit = 20/14 μ – polishing

650 grit = 28/20 μ – polishing

550 grit = 40/28 μ – fine grinding

325 grit = 50/40 μ – fine grinding

285 grit = 63/50 μ – fine grinding

240 grit = 80/63 μ – fine grinding

225 grit = 100/80 μ – fine grinding

160 grit = 125/100 μ – grinding

100 grit = 160/125 μ – grinding

80 grit = 200/165 μ – sharpening / rough grinding

Knife sharpening with combined bond stones

Reviews

There are no reviews yet.