STARTER SETS OF DIAMOND AND CBN SHARPENING STONES, RESIN AND METAL BONDS

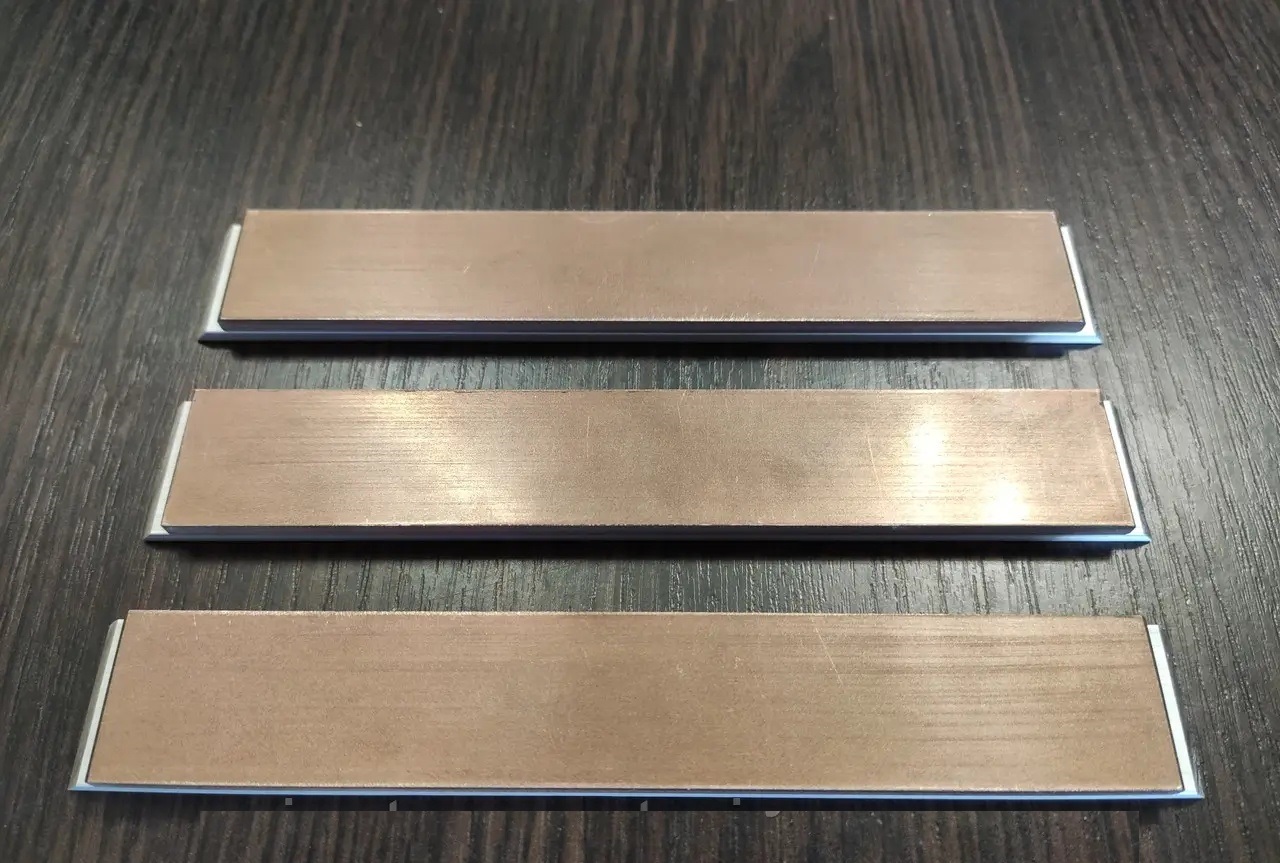

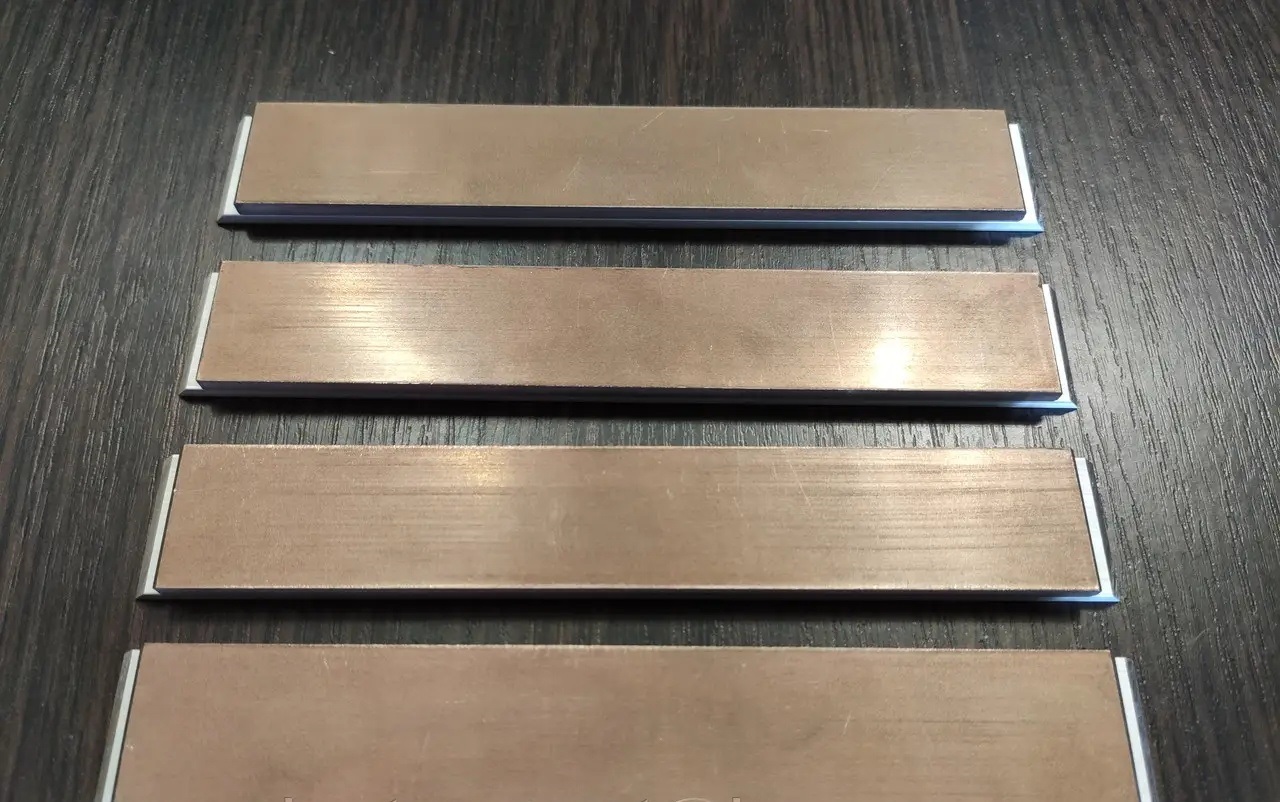

Low cost, but premium quality solution for novice sharpener. Blank is thinner, edges are not beveled, modest packaging, stones need preparation. You may find these stones on eBay or on other internet stones as “Premium Ukrainian sharpening stones”.

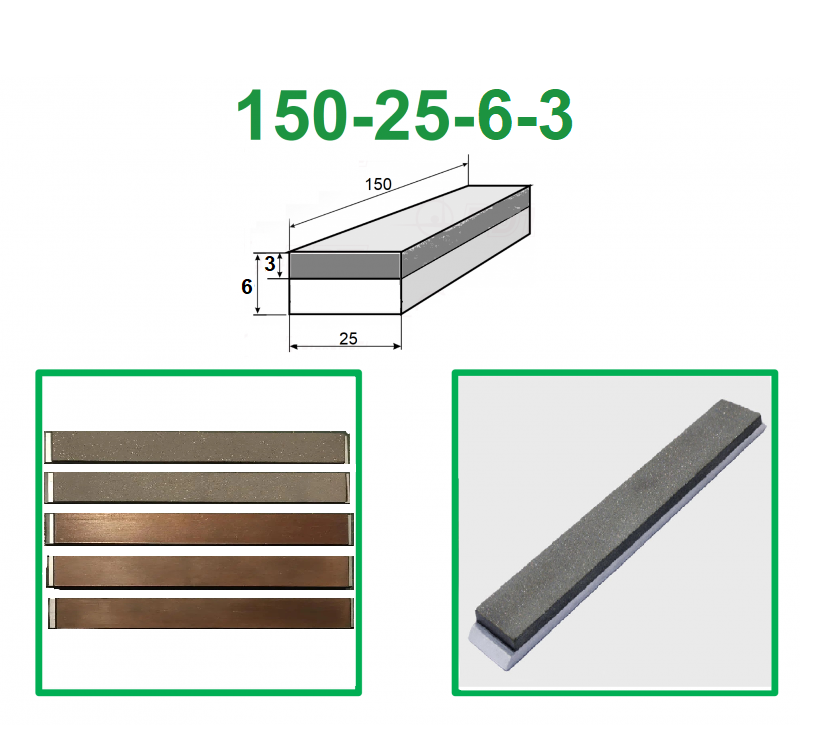

Length: 150 mm = 6 inch

Width: 25 mm = 1 inch

CBN height: 3 mm = 0.1 inch

Total height (with blank): 6 mm = 0.2 inch

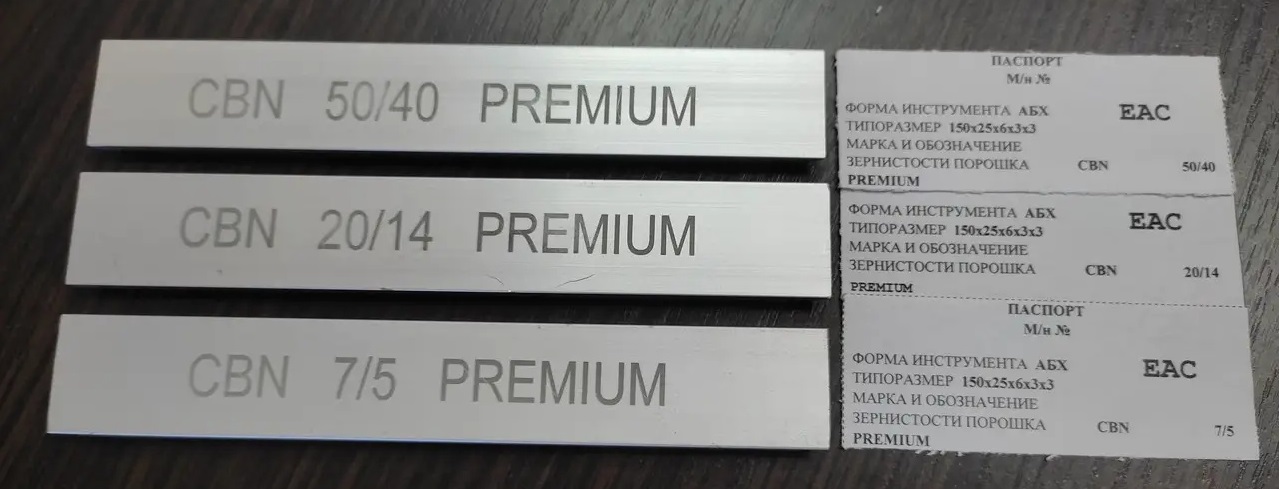

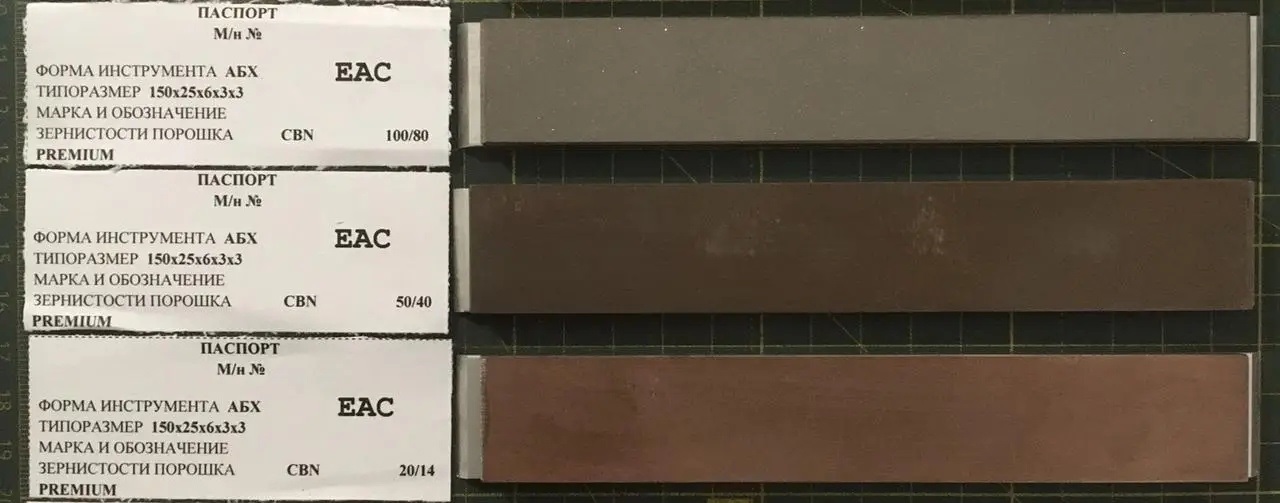

Starter pack # 1, 3 CBN stones, resin bond

F325 (Medium) 50/40μ – fine grinding

F1100 (Very fine) 20/14μ – polishing

F3000 (Extra fine) 7/5 – polishing

Starter pack # 2, 4 CBN stones, metal and resin bond

F225 (Coarse) 100/80μ, metal bond – fine grinding

F325 (Medium) 50/40μ, resin bond – fine grinding

F1100 (Very fine) 20/14μ, resin bond – polishing

F3000 (Extra fine) 7/5, resin bond – polishing

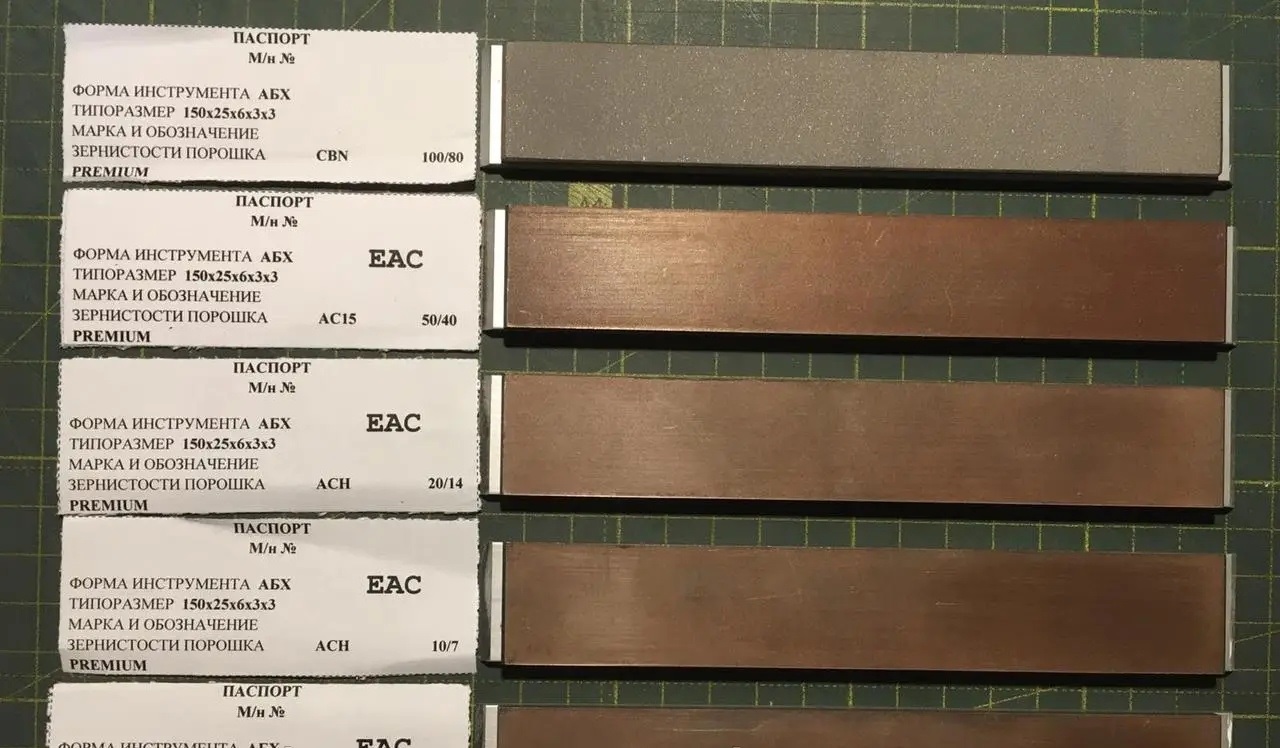

Starter pack # 3, 5 CBN stones, metal and resin bond

F225 (Coarse) 100/80μ, metal bond- fine grinding

F325 (Medium) 50/40μ – fine grinding

F1100 (Very fine) 20/14μ, resin bond – polishing

F1700 (Extra fine) 10/7μ, resin bond – polishing

F4000 (Extra fine) 5/3μ, resin bond – polishing

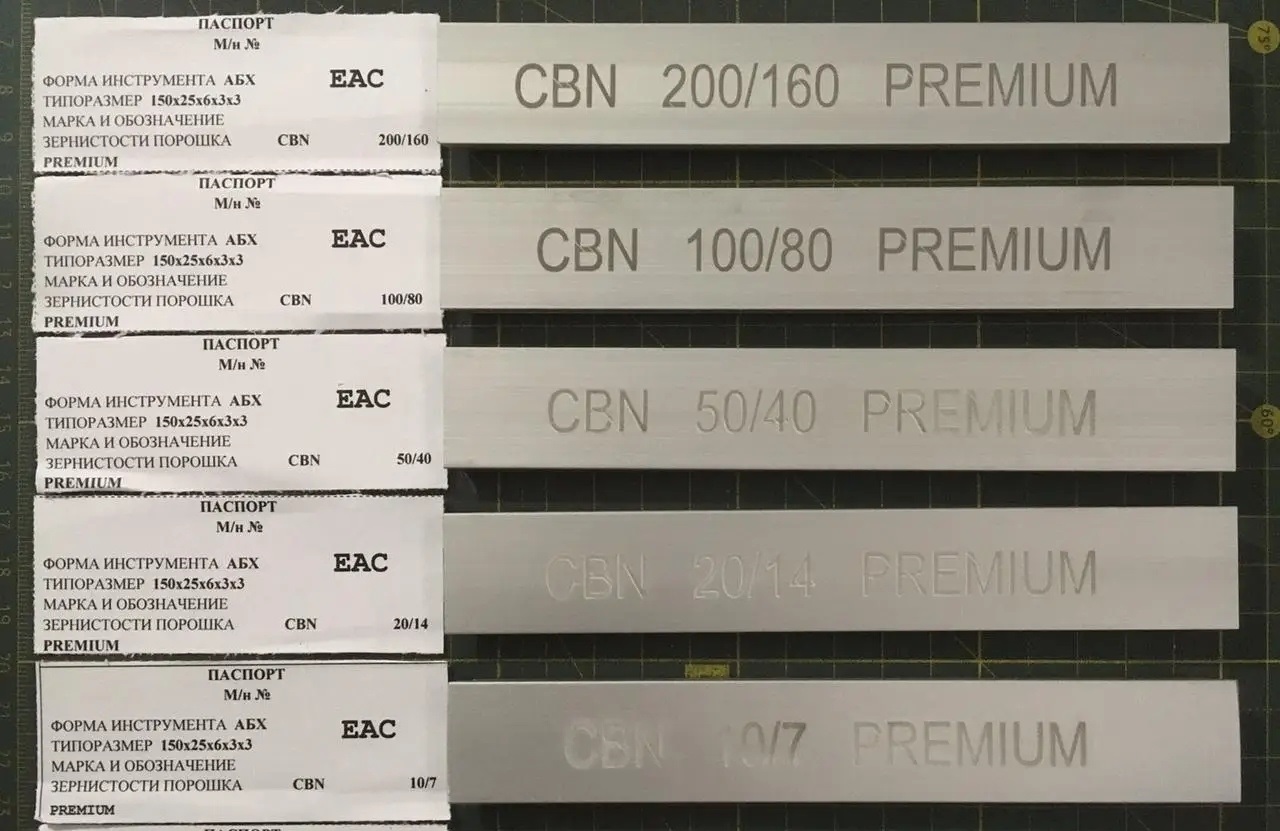

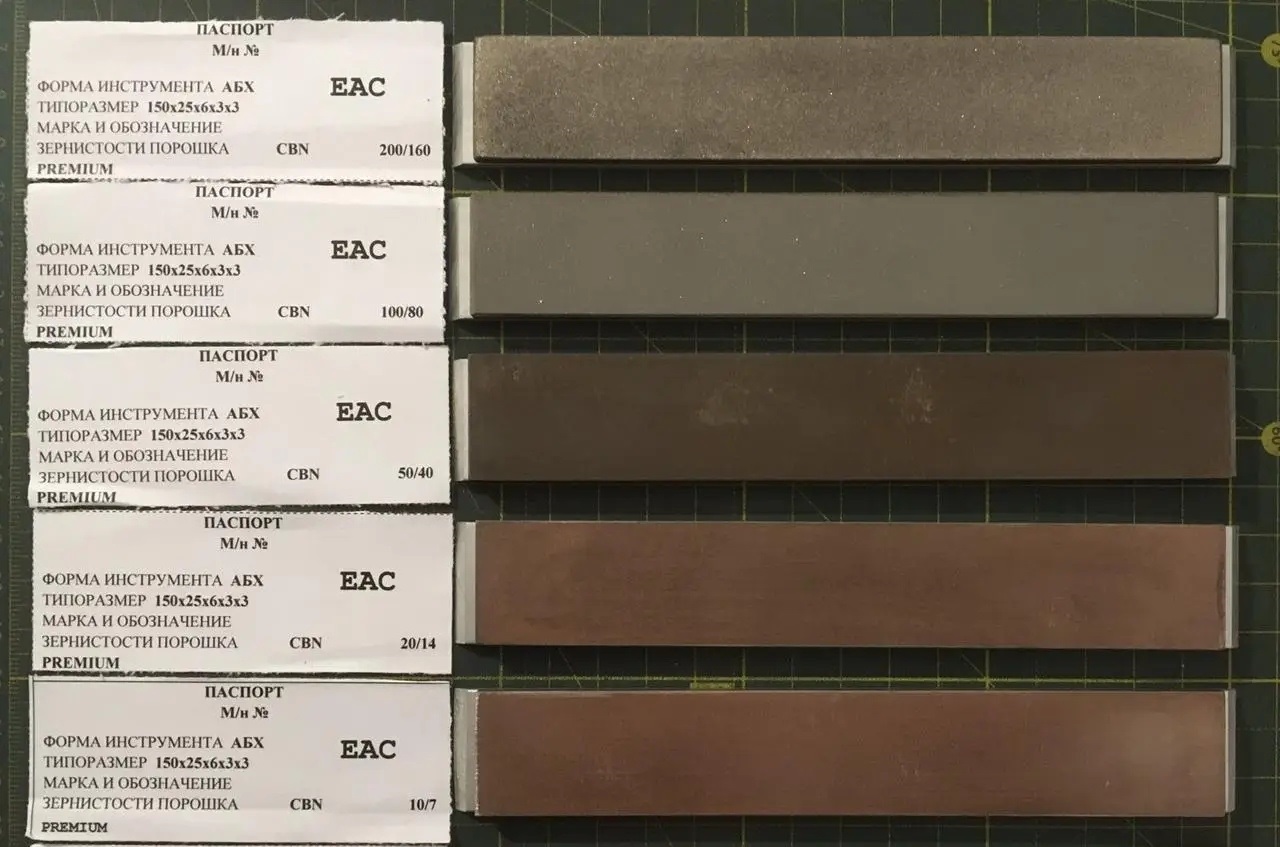

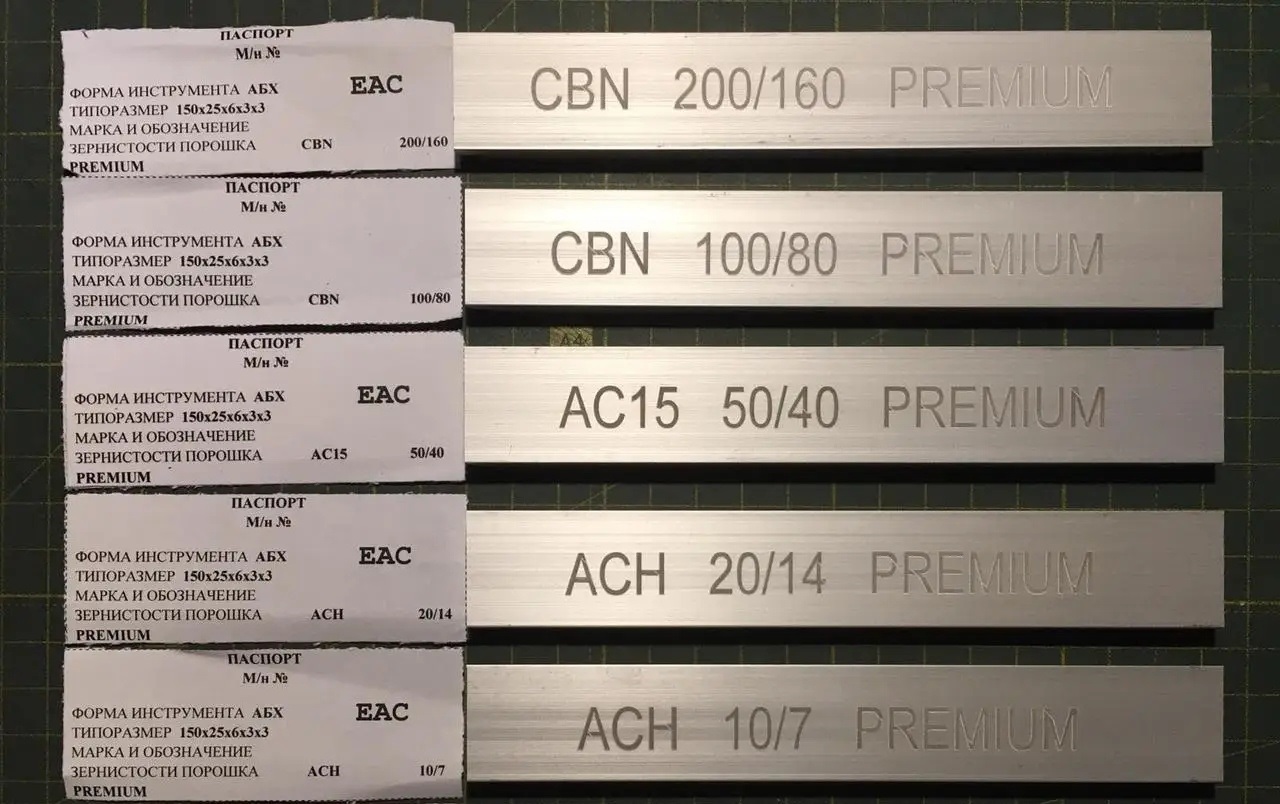

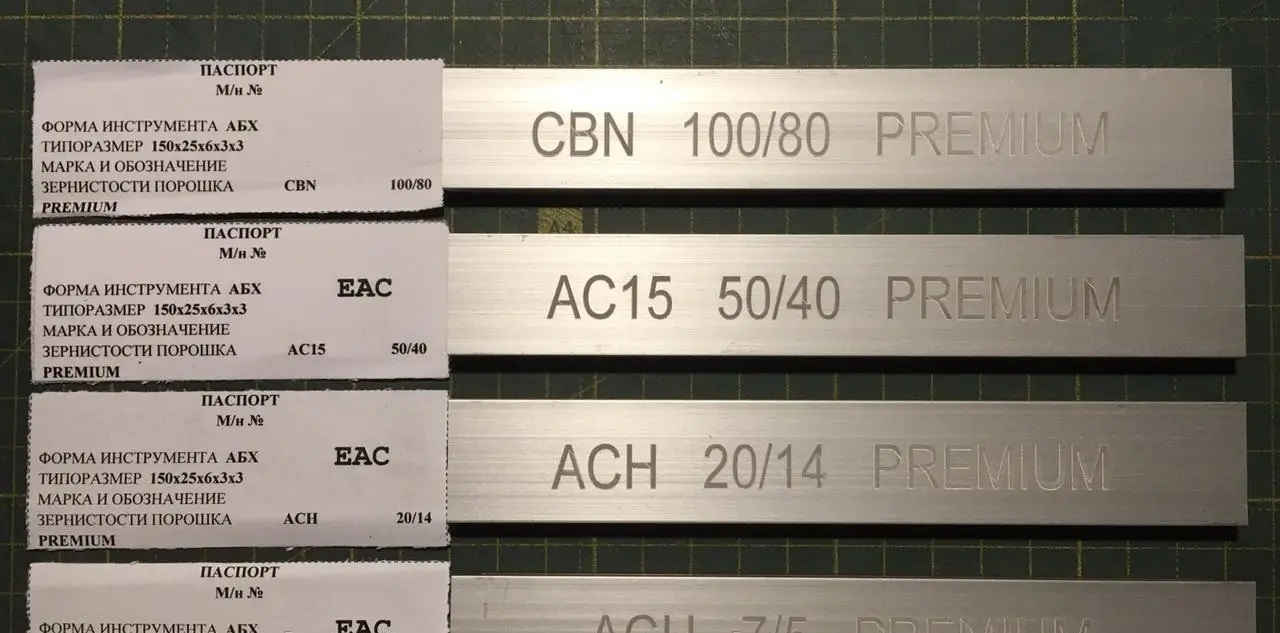

Starter pack # 4, 6 CBN stones, metal and resin bond

F80 (Extra Coarse) 200/160μ, metal bond- sharpening / rough grinding

F225 (Coarse) 100/80μ, metal bond – fine grinding

F325 (Medium) 50/40μ, resin bond – fine grinding

F1100 (Very fine) 20/14μ, resin bond – polishing

F1700 (Extra fine) 10/7μ, resin bond – polishing

F4000 (Extra fine) 5/3μ, resin bond – polishing

Starter pack # 5, 3 Diamond stones, resin bond

F325 (Medium) 50/40μ – fine grinding

F1100 (Very fine) 20/14μ – polishing

F3000 (Extra fine) 7/5 – polishing

Starter pack # 6, 4 Diamond stones, resin bond

F225 (Coarse) 100/80μ – fine grinding

F325 (Medium) 50/40μ – fine grinding

F1100 (Very fine) 20/14μ – polishing

F3000 (Extra fine) 7/5 – polishing

Starter pack # 7, 4 Diamond and CBN stones, metal and resin bond

F225 (Coarse) 100/80μ, CBN, metal bond – fine grinding

F325 (Medium) 50/40μ, diamond, resin bond – fine grinding

F1100 (Very fine) 20/14μ, diamond, resin bond – polishing

F3000 (Extra fine) 7/5, diamond, resin bond – polishing

Starter pack # 8, 5 CBN and diamond stones, metal and resin bonds

F225 (Coarse) 100/80, CBN, metal bond – fine grinding

F325 (Medium) 50/40μ, resin bond – fine grinding

F1100 (Very fine) 20/14μ, diamond, resin bond – polishing

F1700 (Extra fine) 10/7μ, diamond, resin bond – polishing

F4000 (Extra fine) 5/3μ, diamond, resin bond – polishing

Starter pack # 9, 6 CBN stones, metal and resin bond

F80 (Extra Coarse) 200/160μ, CBN, metal bond- sharpening / rough grinding

F225 (Coarse) 100/80μ, CBN, metal bond – fine grinding

F325 (Medium) 50/40μ, diamond, resin bond – fine grinding

F1100 (Very fine) 20/14μ, diamond, resin bond – polishing

F1700 (Extra fine) 10/7μ, diamond, resin bond – polishing

F4000 (Extra fine) 5/3μ, diamond, resin bond – polishing

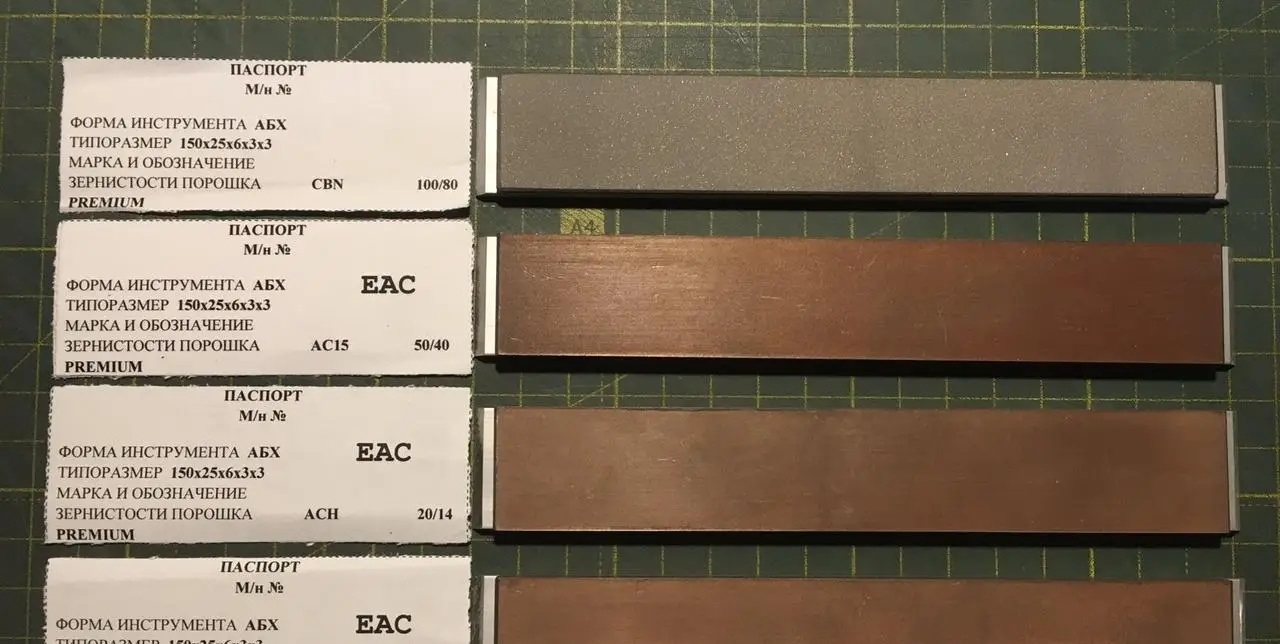

Bonds:

Resin bond: phenol-formaldehyde, does not require lubricant, but you may use water (or water based cooling liquids)

Metal bond: M2-01, copper-tin

Preparation of sharpening stones

These stones require preparation (dressing), or they will be self-polished after sharpening of 30-50 knives. Then they will be of gold color and work well.

This is common issue for all manufacturers: abrasive grains are covered with bond, so you need to “release” them.

Selection of SiC powders for dressing of sharpening stones

| Stone | Starting grit | Finishing grit |

| 500/400 μ = 35/40= D501 | F16 (1230 μ) | F24 (745 μ) |

| 400/315 μ = 40/45= D426 | F16 (1230 μ) | F46 (370 μ) |

| 315/250 μ = 50/60= D301 | F24 (745 μ) | F46 (370 μ) |

| 250/200 μ = 60/70= D251 | F24 (745 μ) | F60 (260 μ) |

| 200/160 μ = 70/80= D213 | F36 (525 μ) | F60 (260 μ) |

| 160/125 μ = 100/120= D151 | F46 (370 μ) | F80 (180 μ) |

| 125/100 μ = 120/140= D126 | F60 (260 μ) | F100 (129 μ) |

| 100/80 μ = 140/170= D107 | F60 (260 μ) | F120 (109 μ) |

| 80/63 μ = 170/200= D91 | F80 (180 μ) | F150 (82 μ) |

| 63/50 μ = 230/270= D64 | F100 (129 μ) | F180 (69 μ) |

| 50/40 μ = 270/325= D54 | F120 (109 μ) | F220 (58 μ) |

| 40/28 μ = 550= M40 | F150 (82 μ) | F240 (46 μ) |

| 28/20 μ = 650= M25 | F180 (69 μ) | F320 (30 μ) |

| 20/14 μ = 1100= M20 | F240 (46 μ) | F400 (18 μ) |

| 14/10 μ = 1500= M16 | F320 (30 μ) | F400 (18 μ) |

| 10/7 μ = 1700= M10 | F400 (18 μ) | F600 (10 μ) |

| 7/5 μ = 3000= M6.3 | F600 (10 μ) | F800 (6,7 μ) |

| 5/3 μ = 4000= M4 | F600 (10 μ) | F800 (6,7 μ) |

| 3/2 μ = 6000= M1.5 | F800 (6,7 μ) | F1200 (3 μ) |

| 2/1 μ = 10000 | F800 (6,7 μ) | F1200 (3 μ) |

| 1/0 μ | F800 (6,7 μ) | F1200 (3 μ) |

| 0.5/0 μ | F800 (6,7 μ) | F1200 (3 μ) |

Use and cleaning of sharpening stones

Use any comfortable oil (baby, olive..) to prevent glazing. If glazed – clean with alcohol and toothbrush.

Reviews

There are no reviews yet.