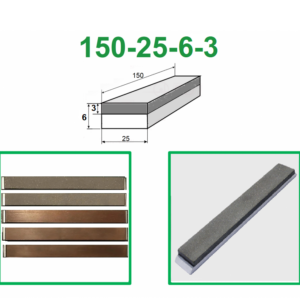

DIAMOND SHARPENING STONES, METAL BOND, CONCENTRATION 100%, NARROW

150-12-7-4-3

Sharpening of curved blades on hand sharpeners, line Edge, Kazak, etc.

Length: 150 mm = 6 inch

Width: 12 mm = 0.5 inch

CBN height: 3 mm = 0.12 inch

Total height (with blank): 7 mm = 0.28 inch

Bonds: Metal M2-01 (copper-tin), Combined (copper-resin, depending on grain size)

Flat solid block on aluminum blank.

Grain concentration: 100%

Do not waste your money on cheaper stones with lower/unknown concentration.

Flat solid block on aluminum blank, abrasive grains are evenly distributed across the volume of the stone.

Preparation of sharpening stones

Unlike other sharpening stones, most of these hybrid bond stones do not need preparation, except stones with grits finer 1 microns (<Grit 15000). Ultrafine grains (1/0, 0.5/0) form agglomerates in a bond, so you may need to dress them with abrasive powders/pastes, or they will be self-polished after sharpening of 30-50 knives.

Selection of SiC powders for dressing of sharpening stones

| Stone | Starting grit | Finishing grit |

| 500/400 μ = 35/40= D501 | F16 (1230 μ) | F24 (745 μ) |

| 400/315 μ = 40/45= D426 | F16 (1230 μ) | F46 (370 μ) |

| 315/250 μ = 50/60= D301 | F24 (745 μ) | F46 (370 μ) |

| 250/200 μ = 60/70= D251 | F24 (745 μ) | F60 (260 μ) |

| 200/160 μ = 70/80= D213 | F36 (525 μ) | F60 (260 μ) |

| 160/125 μ = 100/120= D151 | F46 (370 μ) | F80 (180 μ) |

| 125/100 μ = 120/140= D126 | F60 (260 μ) | F100 (129 μ) |

| 100/80 μ = 140/170= D107 | F60 (260 μ) | F120 (109 μ) |

| 80/63 μ = 170/200= D91 | F80 (180 μ) | F150 (82 μ) |

| 63/50 μ = 230/270= D64 | F100 (129 μ) | F180 (69 μ) |

| 50/40 μ = 270/325= D54 | F120 (109 μ) | F220 (58 μ) |

| 40/28 μ = 550= M40 | F150 (82 μ) | F240 (46 μ) |

| 28/20 μ = 650= M25 | F180 (69 μ) | F320 (30 μ) |

| 20/14 μ = 1100= M20 | F240 (46 μ) | F400 (18 μ) |

| 14/10 μ = 1500= M16 | F320 (30 μ) | F400 (18 μ) |

| 10/7 μ = 1700= M10 | F400 (18 μ) | F600 (10 μ) |

| 7/5 μ = 3000= M6.3 | F600 (10 μ) | F800 (6,7 μ) |

| 5/3 μ = 4000= M4 | F600 (10 μ) | F800 (6,7 μ) |

| 3/2 μ = 6000= M1.5 | F800 (6,7 μ) | F1200 (3 μ) |

| 2/1 μ = 10000 | F800 (6,7 μ) | F1200 (3 μ) |

| 1/0 μ = 15000 | F800 (6,7 μ) | F1200 (3 μ) |

| 0.5/0 μ = 30000 | F800 (6,7 μ) | F1200 (3 μ) |

Use and cleaning of diamond sharpening stones

Use any comfortable oil (baby, olive..) to prevent glazing. If glazed – clean with alcohol and toothbrush.

Maintenance (in 1-2 years), flattening/revitalization – with silicon (silica) carbide powders on glass plate, grain size selection – according to the table above.

Grain size/operation reference chart

30000 grit = 0.5/0 μ – fine polishing

15000 grit = 1/0 μ – fine polishing

10000 grit = 2/1 μ – fine polishing

5000 grit = 3/2 μ – fine polishing

4000 grit = 5/3 μ – polishing

3000 grit = 7/5 μ – polishing

1700 grit = 10/7 μ – polishing

1500 grit = 14/10 μ – polishing

1100 grit = 20/14 μ – polishing

650 grit = 28/20 μ – polishing

550 grit = 40/28 μ – fine grinding

325 grit = 50/40 μ – fine grinding

285 grit = 63/50 μ – fine grinding

240 grit = 80/63 μ – fine grinding

225 grit = 100/80 μ – fine grinding

160 grit = 125/100 μ – grinding

100 grit = 160/125 μ – grinding

80 grit = 200/165 μ – sharpening / rough grinding

Knife sharpening with combined bond stones

Reviews

There are no reviews yet.