CBN (CUBIC BORON NITRIDE, BORAZON) SHARPENING STONES, METAL AND COMBINED BONDS, CONCENTRATION 100%, NARROW

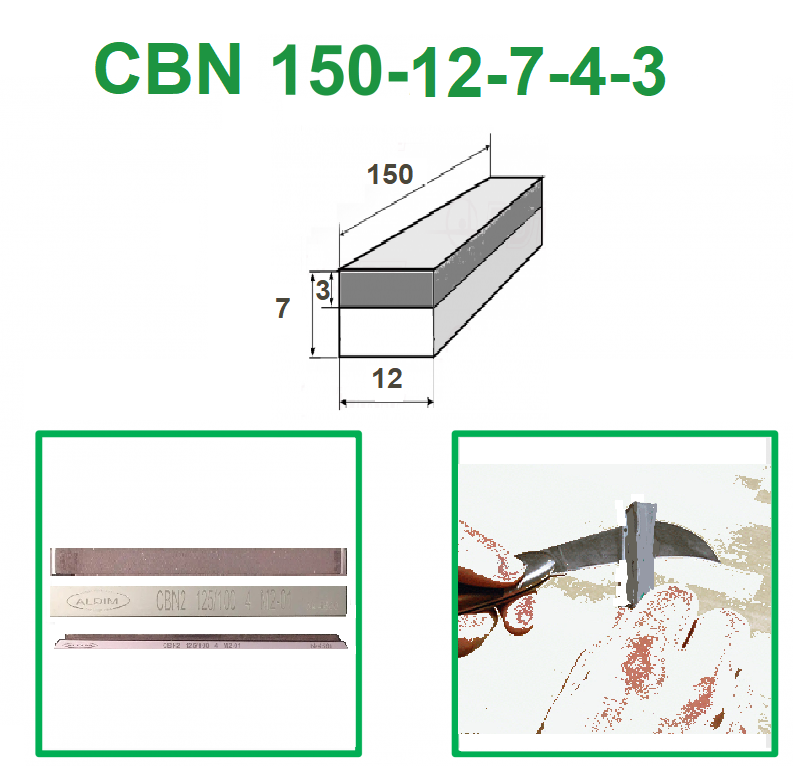

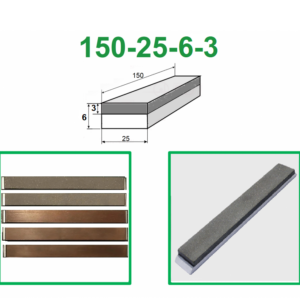

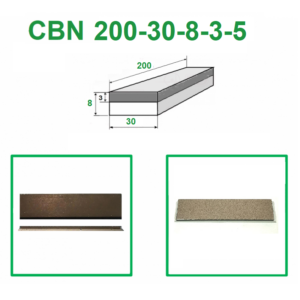

150-12-7-4-3

For sharpening of curved blades using hand sharpeners: Hapstone, Edge, Kazak, etc.

Length: 150 mm = 6 inch

Width: 12 mm = 0.5 inch

CBN height: 3 mm = 0.12 inch

Total height (with blank): 7 mm = 0.28 inch

Bonds: Metal M2-01 (copper-tin), Combined (copper-resin, depending on grain size) Flat solid block on aluminum blank.

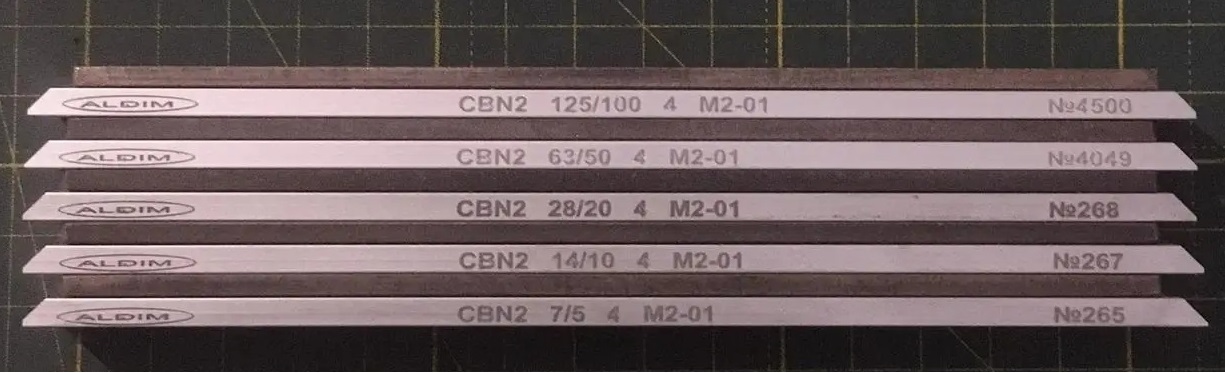

Grain size: Please select from the list

MESH(GRIT) = MICRON

Grain concentration: 100%

Do not waste your money on cheaper stones with lower/unknown concentration.

Preparation of sharpening stones

Stones with grits finer 3 microns either require preparation (dressing), or they will be self-polished after sharpening of 30-50 knives. Then they will be of gold color and work well. This is common issue for all manufacturers: abrasive grains are covered with bond, so you need to “release” them.

Selection of SiC powders for dressing of sharpening stones

| Stone | Starting grit | Finishing grit |

| 500/400 μ = 35/40= D501 | F16 (1230 μ) | F24 (745 μ) |

| 400/315 μ = 40/45= D426 | F16 (1230 μ) | F46 (370 μ) |

| 315/250 μ = 50/60= D301 | F24 (745 μ) | F46 (370 μ) |

| 250/200 μ = 60/70= D251 | F24 (745 μ) | F60 (260 μ) |

| 200/160 μ = 70/80= D213 | F36 (525 μ) | F60 (260 μ) |

| 160/125 μ = 100/120= D151 | F46 (370 μ) | F80 (180 μ) |

| 125/100 μ = 120/140= D126 | F60 (260 μ) | F100 (129 μ) |

| 100/80 μ = 140/170= D107 | F60 (260 μ) | F120 (109 μ) |

| 80/63 μ = 170/200= D91 | F80 (180 μ) | F150 (82 μ) |

| 63/50 μ = 230/270= D64 | F100 (129 μ) | F180 (69 μ) |

| 50/40 μ = 270/325= D54 | F120 (109 μ) | F220 (58 μ) |

| 40/28 μ = 550= M40 | F150 (82 μ) | F240 (46 μ) |

| 28/20 μ = 650= M25 | F180 (69 μ) | F320 (30 μ) |

| 20/14 μ = 1100= M20 | F240 (46 μ) | F400 (18 μ) |

| 14/10 μ = 1500= M16 | F320 (30 μ) | F400 (18 μ) |

| 10/7 μ = 1700= M10 | F400 (18 μ) | F600 (10 μ) |

| 7/5 μ = 3000= M6.3 | F600 (10 μ) | F800 (6,7 μ) |

| 5/3 μ = 4000= M4 | F600 (10 μ) | F800 (6,7 μ) |

| 3/2 μ = 6000= M1.5 | F800 (6,7 μ) | F1200 (3 μ) |

| 2/1 μ = 10000 | F800 (6,7 μ) | F1200 (3 μ) |

| 1/0 μ | F800 (6,7 μ) | F1200 (3 μ) |

| 0.5/0 μ | F800 (6,7 μ) |

Use and cleaning of sharpening stones

Use any comfortable oil (baby, olive..) to prevent glazing. If glazed – clean with alcohol and toothbrush.

Maintenance (in 1-2 year), flattening/revitalization: with silicon (silica) carbide powders on glass plate, making slow polishing movements, similar to drawing digit 8.

Grain size/operation reference chart

30000 grit = 0.5/0 μ – fine polishing

15000 grit = 1/0 μ – fine polishing

10000 grit = 2/1 μ – fine polishing

5000 grit = 3/2 μ – fine polishing

4000 grit = 5/3 μ – polishing

3000 grit = 7/5 μ – polishing

1700 grit = 10/7 μ – polishing

1500 grit = 14/10 μ – polishing

1100 grit = 20/14 μ – polishing

650 grit = 28/20 μ – polishing

550 grit = 40/28 μ – fine grinding

325 grit = 50/40 μ – fine grinding

285 grit = 63/50 μ – fine grinding

240 grit = 80/63 μ – fine grinding

225 grit = 100/80 μ – fine grinding

160 grit = 125/100 μ – grinding

100 grit = 160/125 μ – grinding

80 grit = 200/165 μ – sharpening / rough grinding

Reviews

There are no reviews yet.